Maximize the precision and performance of your machinery with ball bar testing, a service offered by Machine Ethics. Knowledgable in industrial machine maintenance and optimization, we specialize in conducting ball-bar tests to assess and enhance the accuracy of machine tools.

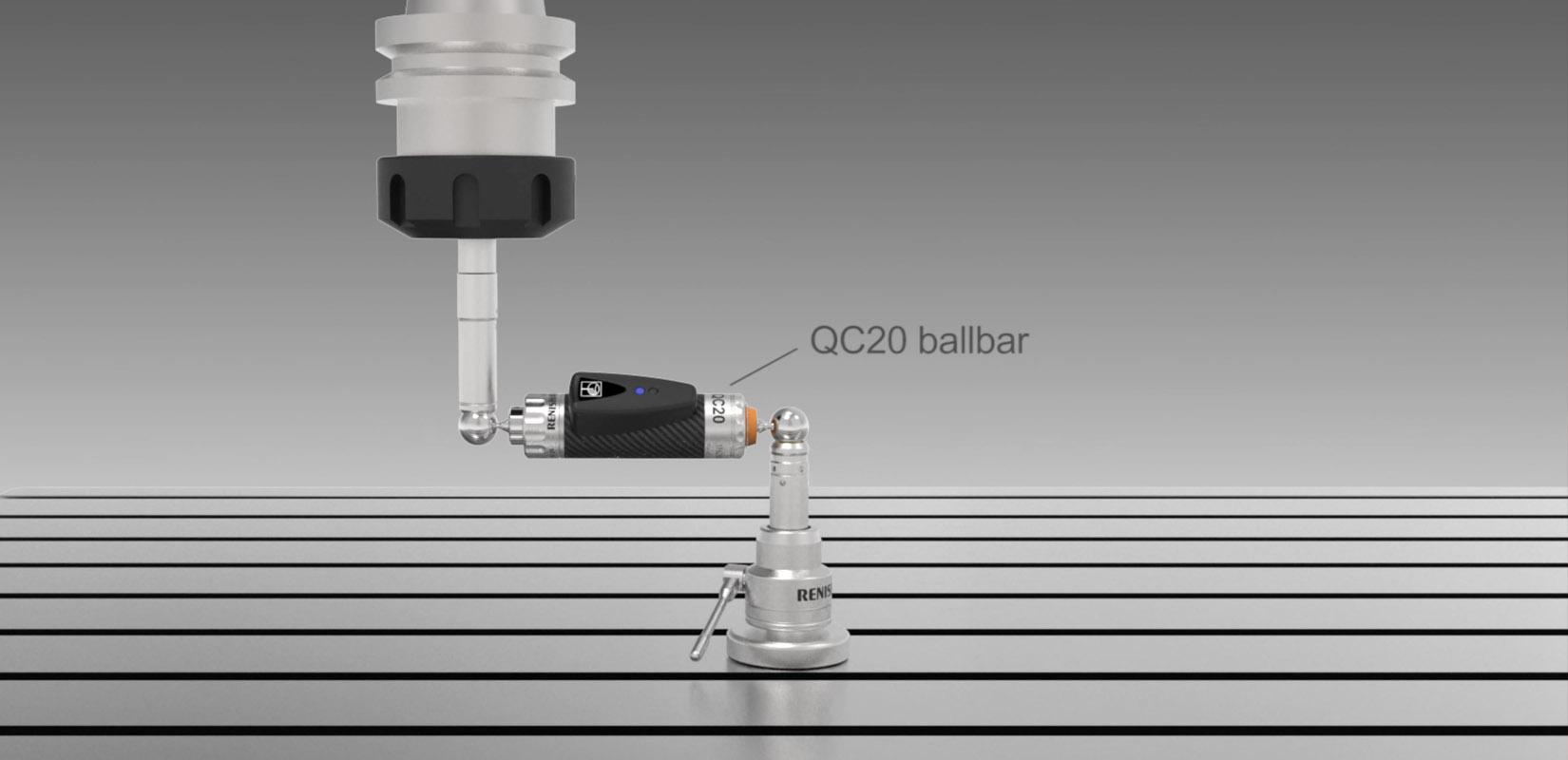

With our extensive experience and training with Renishaw, a leading provider of metrology solutions, we are fully equipped to perform ball-bar testing on a wide range of machines, helping our clients achieve superior results and maintain a competitive edge in their industries.

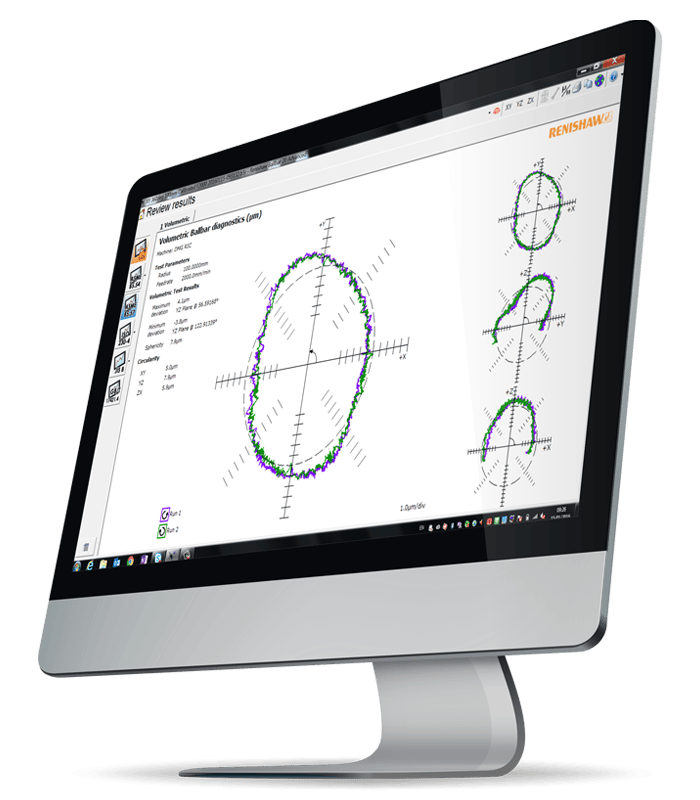

Ball bar testing, also known as circular geometry testing, is a highly effective method for evaluating the dynamic performance of machine tools.

By simulating real-world machining conditions, ball bar tests can identify and quantify various sources of error in machine motion, such as backlash, geometric errors, and servo performance issues.

This valuable diagnostic data enables us to pinpoint areas for improvement and implement corrective measures to optimize machine accuracy and reliability.

YOU ARE IN GOOD HANDS

At Machine Ethics, we understand the critical importance of precision in manufacturing processes. That’s why we offer comprehensive ball bar testing services to help our clients ensure that their machines are operating at peak performance levels.

Our skilled technicians use state-of-the-art equipment and advanced measurement techniques to conduct thorough ball bar tests, providing detailed insights into machine behavior and performance.

MAXIMIZE PRECISION

One of the key advantages of ball bar testing is its ability to detect and diagnose subtle deviations in machine motion that may not be apparent during normal operation.

By analyzing the data collected from ball bar tests, we can identify potential issues early on and take proactive steps to address them before they escalate into more serious problems.

This proactive approach helps our clients minimize downtime, reduce scrap and rework, and optimize overall productivity.

Our team of technicians boasts extensive training and expertise, specializing in the meticulous execution of ball bar tests across a diverse range of machinery. Possessing a profound comprehension of metrology principles and adhering to industry-best practices, we are well-equipped to provide precise, dependable, and insightful results. Through our commitment to excellence, we ensure that our clients receive unparalleled service, backed by the proficiency and knowledge of our highly skilled professionals.

Utilizing cutting-edge measurement tools and software, such as the Renishaw ball bar systems, is integral to our commitment to achieving the utmost precision and accuracy in our testing procedures.

Our state-of-the-art equipment and sophisticated software solutions underscore our dedication to employing the latest technological advancements. This advanced technology enhances the efficiency of our processes and reinforces our ability to deliver results that meet the highest standards of quality and reliability.

By integrating these innovative tools, we consistently strive to stay at the forefront of the industry, providing our clients with unparalleled testing capabilities and ensuring the optimal performance of various machines across diverse applications.

Our commitment to client satisfaction is reflected in our approach to ball-bar testing services, where we meticulously tailor our offerings to address each client’s unique needs and requirements. Whether the goal is to pinpoint and diagnose a specific issue or conduct a comprehensive evaluation of the overall machine performance, we pride ourselves on our ability to develop customized testing plans that align precisely with our client’s objectives.

By understanding the intricacies of their operational context, we can craft solutions that meet and exceed expectations. Our emphasis on providing personalized and bespoke testing services ensures that our clients receive accurate and insightful results and a tailored approach that adds value to their specific operational challenges.

Through this commitment to customized solutions, we strive to foster long-term partnerships built on trust, reliability, and the delivery of precisely tailored testing strategies.

At Machine Ethics, our dedication to customer satisfaction goes beyond just testing. We provide continuous support to assist clients in implementing recommended improvements and optimizing their machine performance over time.

Our collaborative approach involves working closely with clients to understand their unique challenges and goals, allowing us to offer tailored recommendations and hands-on assistance. With a commitment to staying updated on industry advancements, we ensure ongoing support that addresses evolving needs.

At Machine Ethics, our focus is on testing and being a reliable, long-term partner for our clients, fostering a relationship built on trust and sustained excellence.

Machine Ethics’ ball bar testing services are suitable for a wide range of machine tools, including CNC mills, lathes, machining centers, and more. Whether you’re experiencing issues with dimensional accuracy, surface finish quality, or part consistency, our comprehensive testing and analysis process can help you identify the root causes and implement effective solutions to improve performance.

In today’s competitive manufacturing environment, precision and accuracy are essential for success. With ball-bar testing from Machine Ethics, you can ensure that your machines operate at the highest performance, reliability, and efficiency levels.

Contact us today to learn more about our ball-bar testing services and how we can help you maximize the potential of your machinery.